Vakuumtransportør Producent

-

ZKS fint pulver vakuumtransportør

ZKS Vacuum -feeder bruger en vakuumpumpe til at trække luften, så indløbet af sugedysen og hele systemet er i en bestemt vakuumtilstand. ... -

ZKS rustfrit stål madpulver vakuumtransportør

ZKS Rustfrit stål madpulver vakuumtransportør er et vakuumtransportør i rustfrit stål designet til hygiejnisk håndtering af fødevarepulve... -

ZKS rustfrit stål pulver vakuumtransportør

ZKS -vakuumtransportøren i rustfrit stål er et vakuumtransportør i rustfrit stål designet til hygiejnisk håndtering af fødevarepulvere.

ZKS Vacuum -feeder bruger en vakuumpumpe til at trække luften, så indløbet af sugedysen og hele systemet er i en bestemt vakuumtilstand. Pulverpartiklerne suges ind i dysen sammen med den udvendige luft for at danne en luftstrøm, der passerer gennem sugerøret og når hopperen. Det adskilte materiale indgår i det modtagende udstyr. Fodrings- og udledningsenheden afsluttes ved kontinuerligt at åbne og lukke den pneumatiske trevejsventil, og den kontrolleres af kontrolpanelet.

Om os

Ære

-

Ære

Ære -

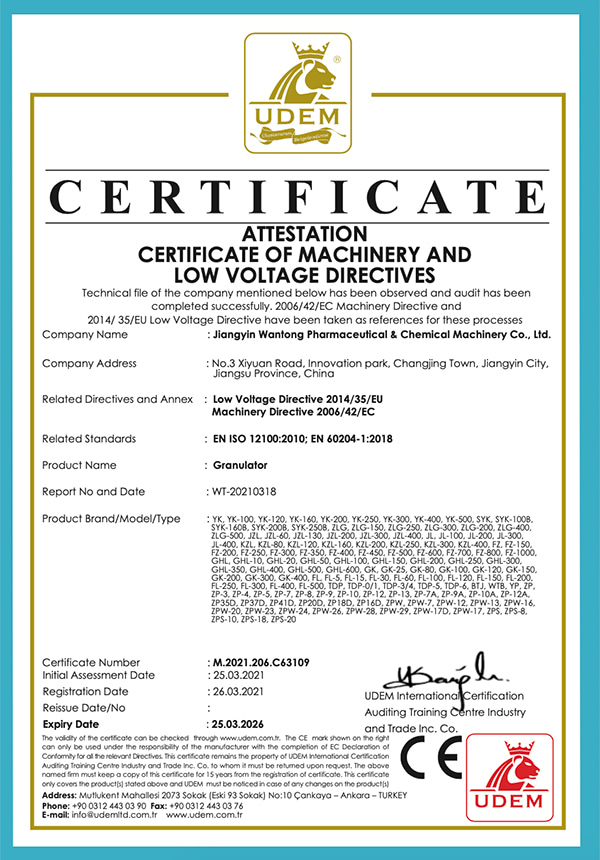

Ce

Ce

Nyheder

-

Industri -nyheder 2026-01-06

Introduktion til krydderslibemaskiner Kværnemaskiner til krydderier er essentielt udstyr...

Se mere -

Industri -nyheder 2026-01-04

Introduktion til industrielle tørremetoder Tørring er en kritisk proces i farmaceutisk, kemisk...

Se mere -

Industri -nyheder 2025-12-23

Introduktion til Dobbeltkegleblendere Dobbeltkegleblendere er udbredte industrielle blan...

Se mere -

Industri -nyheder 2025-12-18

Introduktion til Krydderi slibemaskiner Krydderiformalingsmaskiner er essentielle værktø...

Se mere

Udvidelse af branchens viden

What is the design philosophy behind using a vacuum conveyor for handling dry powder materials?

The design philosophy behind using a vacuum conveyor for handling dry powder materials includes several key considerations:

Gentle Material Handling: Vacuum conveyors are designed to handle materials gently to prevent damage or degradation, which is particularly important for delicate dry powders.

Containment and Dust Control: They provide a closed environment that contains the material, preventing dust from escaping into the air, which is beneficial for both the work environment and the product quality.

Accuracy and Precision: Vacuum conveyors allow for precise control over the material flow, which is crucial for applications that require accurate dosing or measurement of powders.

Minimal Contamination Risk: The closed system of a vacuum conveyor reduces the risk of contamination from the surrounding environment, ensuring the purity of the conveyed material.

Ease of Cleaning and Sanitization: Vacuum conveyors are often designed to be easily disassembled for cleaning, which is essential in industries with strict hygiene requirements.

Space Efficiency: They can move materials in various directions (horizontally, vertically, or at an incline), making them suitable for compact spaces or multi-level facilities.

Automation Compatibility: Vacuum conveyors can be integrated into automated systems, streamlining the production process and reducing the need for manual labor.

Versatility: While suitable for dry powders, vacuum conveyors can be adapted for other types of materials, offering flexibility in their use.

Safety: The enclosed design of vacuum conveyors enhances safety by reducing exposure to moving parts.

Energy Efficiency: Vacuum conveyors can be more energy-efficient for certain applications, especially where precise control of material flow is required.

Traceability: They can be part of a system that allows for the tracking of materials, which is important for quality assurance and regulatory compliance.

The design of a vacuum conveyor is centered around creating a system that is gentle on the product, easy to control, clean, and maintain, and that can be integrated into larger automated systems for efficiency and safety.